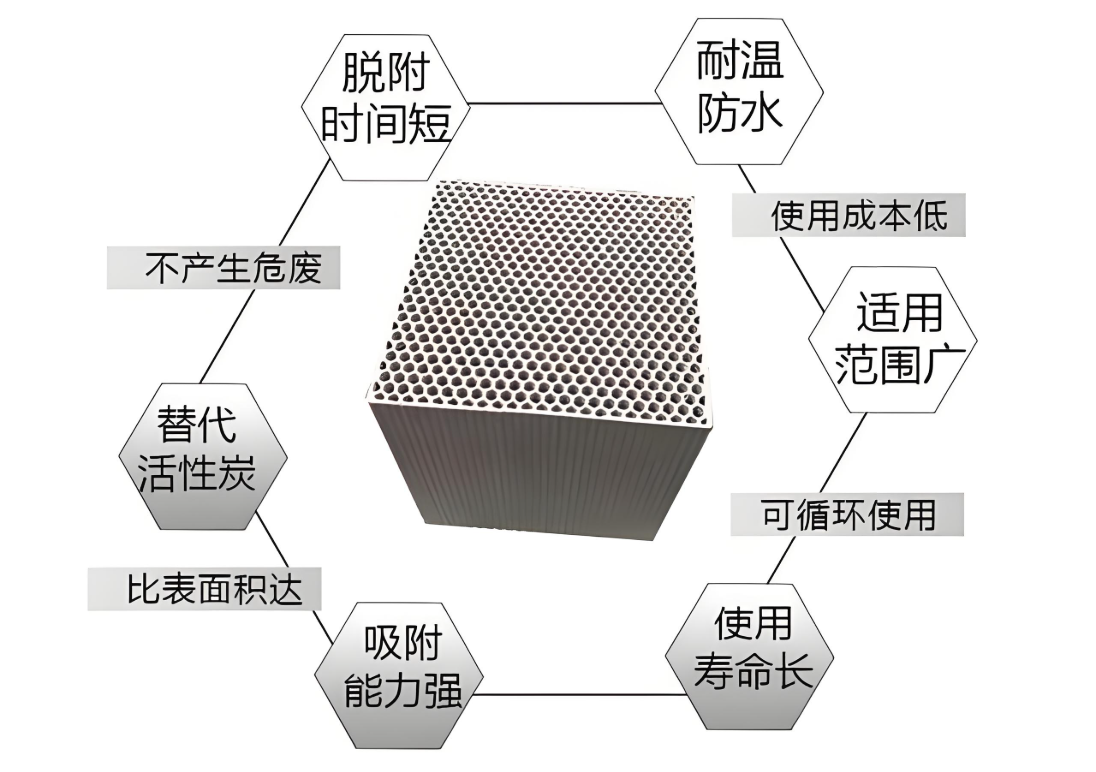

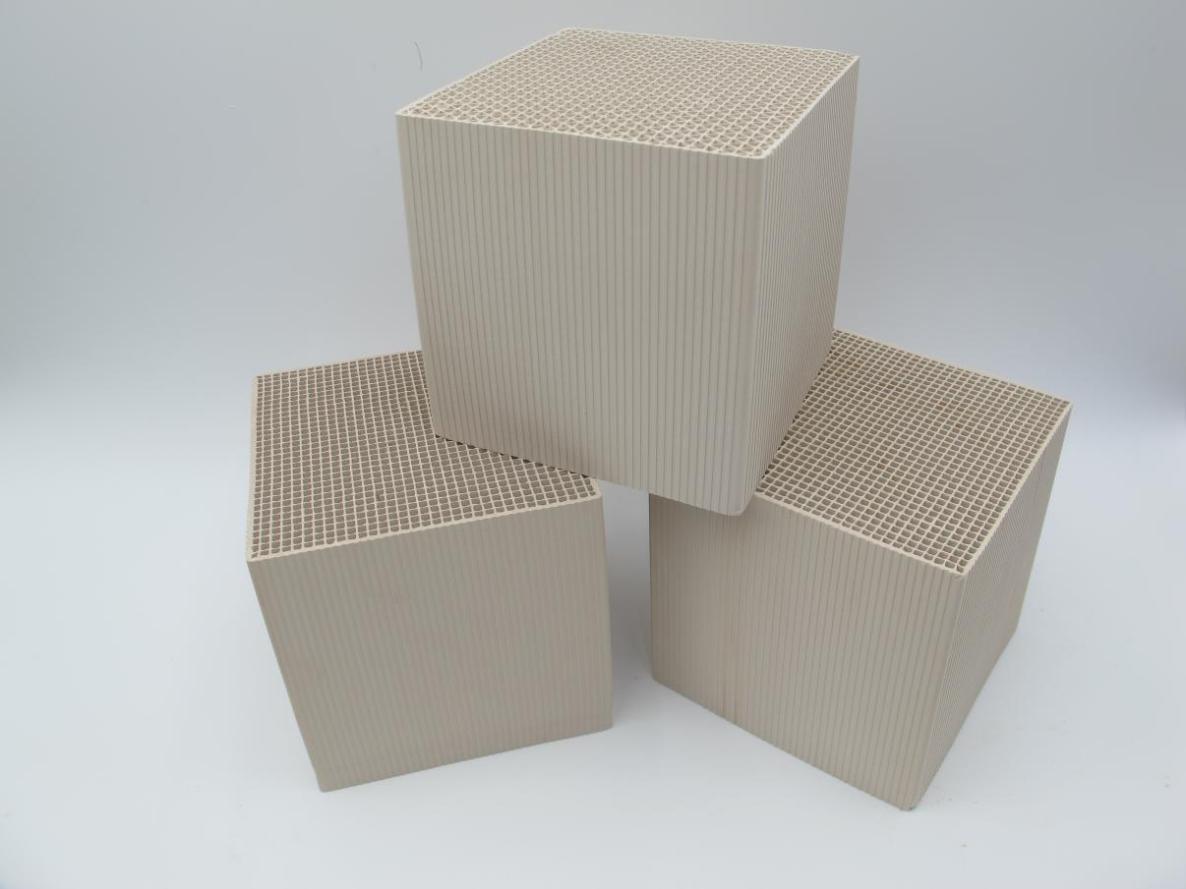

High-performance cellular zeolite molecular sieve: An excellent choice for VOCs treatment

2025-03-26

Strong adsorption capacity Large capacity

Honeycomb zeolite molecular sieves possess amazing adsorption capacity and ultra-large capacity. Their unique nano-scale pore size is precisely designed to accurately match VOCs molecular size, exhibiting excellent selective adsorption capacity. Whether it's common benzene compounds, aldehydes, or esters and other VOC components, they can all be strongly adsorbed. It is particularly outstanding in handling low-concentration VOC

waste gas. Through advanced adsorption and concentration processes, it ensures that waste gas emissions fully comply with the country's strict emission standards, providing strong support for enterprises to achieve environmental compliance. Good hydrophobicity

Low energy consumption

Honeycomb zeolite molecular sieves demonstrate excellent performance in hydrophobicity and energy consumption control. It is carefully prepared using a special process and has a high silica-to-alumina ratio, giving it excellent hydrophobicity. When the environmental humidity is ≤80%, its adsorption performance retention rate is >90%, greatly reducing the adverse effects of humidity on adsorption. Its innovative honeycomb-shaped channel design is another highlight. Compared with traditional granular fillers, the pressure drop is reduced by more than 50%, significantly reducing system operating energy consumption. This means that while efficiently treating waste gas, it can also save companies considerable operating costs.

Good safety

Non-flammable Safety is another significant advantage of honeycomb zeolite molecular sieves. Its main component is aluminosilicate, which does not contain any combustible substances, eliminating the risk of spontaneous combustion from the source, making it safe and reliable during use. More importantly, it is not considered hazardous waste and does not require complex and costly harmless treatment, further reducing the environmental burden on enterprises.

Complete desorption High temperature resistance

Honeycomb zeolite molecular sieves can easily handle the challenges of high-temperature waste gas pretreatment and high-boiling point VOC component treatment. Its stable framework structure allows it to adapt well to high-temperature waste gas pretreatment scenarios. For high-boiling point VOC components, high-temperature desorption can be carried out in the temperature range of 160-350℃, with a maximum temperature resistance of up to 650℃. During high-temperature desorption, not only can complete desorption be achieved, but after multiple regenerations, the overall performance remains stable, with an ultra-long service life. This means that enterprises do not need to frequently replace equipment, greatly reducing long-term use costs.

Wide range of applications

Customizable In addition, honeycomb zeolite molecular sieves have a wide range of applications and are highly customizable. Whether it's different industries such as chemicals, coatings, and printing, or complex and variable operating conditions, products can be customized according to the specific needs of the enterprise. From specifications and shape to adsorption performance, precise matching can be achieved, providing enterprises with solutions that best meet their actual needs.

Previous Page

Previous Page:

Recommended News

Basic principles of molecular sieves

2025-06-13

Types and Selection of Molecular Sieves

2025-06-13

Application cases of molecular sieves

2025-06-13